1 Isakhiwo sangaphakathi sephrinta yelaser

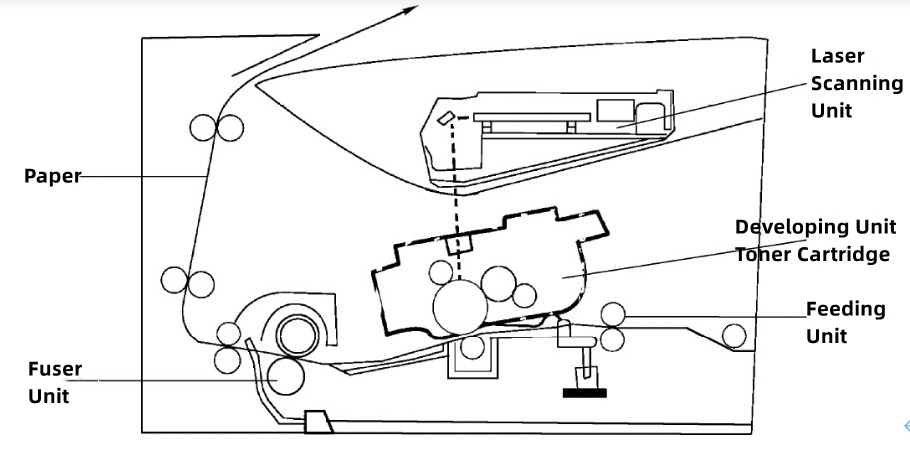

Isakhiwo sangaphakathi sephrinta yelaser sakhiwe izingxenye ezine eziyinhloko, njengoba kuboniswe kuMfanekiso 2-13.

Umfanekiso 2-13 Isakhiwo sangaphakathi sephrinta yelaser

(1) Iyunithi yeLaser: ikhipha umsebe welaser onolwazi lombhalo ukuze iveze isigubhu esizwela ukukhanya.

(2) Iyunithi Yokuphakela Iphepha: lawula iphepha ukuthi lingene kuphrinta ngesikhathi esifanele bese uphuma kuphrinta.

(3) Iyunithi Yokuthuthukisa: Mboza ingxenye eveziwe yesigubhu esizwela ukukhanya nge-toner ukuze wakhe isithombe esingabonakala ngamehlo enyama, bese usidlulisela ebusweni bephepha.

(4) Iyunithi Yokulungisa: I-toner emboze ubuso bephepha iyancibilika futhi iqiniswe ngokuqinile ephepheni kusetshenziswa ingcindezi nokushisa.

2 Isimiso sokusebenza sephrinta ye-laser

Iphrinta ye-laser iyithuluzi lokukhipha elihlanganisa ubuchwepheshe bokuskena nge-laser kanye nobuchwepheshe bokuthwebula izithombe nge-elekthronikhi. Amaphrinta e-laser anemisebenzi ehlukene ngenxa yamamodeli ahlukene, kodwa ukulandelana kokusebenza kanye nesimiso kuyafana.

Uma sithatha amaphrinta e-laser e-HP ajwayelekile njengesibonelo, ukulandelana kokusebenza kungokulandelayo.

(1) Uma umsebenzisi ethumela umyalo wokuphrinta kuphrinta ngesistimu yokusebenza yekhompyutha, ulwazi lwesithombe oluzophrintwa luqala luguqulwe lube ulwazi oluyi-binary nge-driver yephrinta, bese ekugcineni luthunyelwa ebhodini lokulawula eliyinhloko.

(2) Ibhodi lokulawula eliyinhloko lithola futhi lihumushe ulwazi oluyi-binary oluthunyelwe ngumshayeli, lilulungise lube yi-laser beam, futhi lilawule ingxenye ye-laser ukuze ikhiphe ukukhanya ngokusho kwalolu lwazi. Ngesikhathi esifanayo, ubuso besigubhu esinokukhanya bushajwa yidivayisi yokushaja. Bese kuthi i-laser beam enolwazi olunezithombe ikhiqizwe yingxenye yokuskena ye-laser ukuze iveze isigubhu esinokukhanya. Isithombe esicashile se-electrostatic sakhiwe phezu kwesigubhu se-toner ngemva kokuvezwa.

(3) Ngemva kokuba ikhatriji ye-toner ithintane nohlelo olusathuthuka, isithombe esifihliwe siba yimifanekiso ebonakalayo. Uma idlula ohlelweni lokudlulisa, i-toner idluliselwa ephepheni ngaphansi kwesenzo sensimu kagesi yedivayisi yokudlulisa.

(4) Ngemva kokuqedwa kokudluliselwa, iphepha lithinta i-sawtooth eqeda ugesi, bese likhipha ishaja ephepheni liye phansi. Ekugcineni, lingena ohlelweni lokulungisa izinga lokushisa eliphezulu, futhi ihluzo nombhalo owakhiwe yi-toner kuhlanganiswe ephepheni.

(5) Ngemva kokuba ulwazi oluqoshwe ngesithombe luphrintiwe, idivayisi yokuhlanza isusa i-toner engadlulisiwe, bese ingena emjikelezweni olandelayo wokusebenza.

Zonke izinqubo zokusebenza ezingenhla zidinga ukudlula ezinyathelweni eziyisikhombisa: ukushaja, ukuvezwa, ukuthuthukiswa, ukudluliselwa, ukususwa kukagesi, ukulungiswa, kanye nokuhlanza.

1>. Ishaja

Ukuze isigubhu esinozwelo lokubona simunce i-toner ngokwemininingwane yesithombe, isigubhu esinozwelo lokubona kumele sishajwe kuqala.

Okwamanje kunezindlela ezimbili zokushaja zamaphrinta emakethe, enye ukushaja nge-corona kanti enye ukushaja nge-roller roller, zombili ezinezimpawu zazo.

Ukushaja kwe-Corona kuyindlela yokushaja engaqondile esebenzisa i-substrate eqhubayo yesigubhu esizwela ukukhanya njenge-electrode, futhi ucingo lwensimbi oluncane kakhulu lubekwa eduze kwesigubhu esizwela ukukhanya njengenye i-electrode. Lapho kukopishwa noma kunyatheliswa, kufakwa i-voltage ephezulu kakhulu entanjeni, futhi isikhala esizungeze ucingo sakha insimu kagesi enamandla. Ngaphansi kwesenzo sensimu kagesi, ama-ion ane-polarity efanayo nentambo ye-corona ageleza ebusweni besigubhu esizwela ukukhanya. Njengoba i-photoreceptor ebusweni besigubhu esizwela ukukhanya inokumelana okuphezulu ebumnyameni, ishaja ngeke igeleze, ngakho-ke amandla ongaphezulu esigubhu esizwela ukukhanya azoqhubeka ekhuphuka. Lapho amandla enyuka eba namandla aphezulu okwamukelwa, inqubo yokushaja iyaphela. Ububi bale ndlela yokushaja ukuthi kulula ukukhiqiza imisebe ne-ozone.

Ukushaja i-charging roller kuyindlela yokushaja yokuxhumana, engadingi i-voltage ephezulu yokushaja futhi enobungani nemvelo. Ngakho-ke, amaphrinta amaningi e-laser asebenzisa ama-charging roller ukushaja.

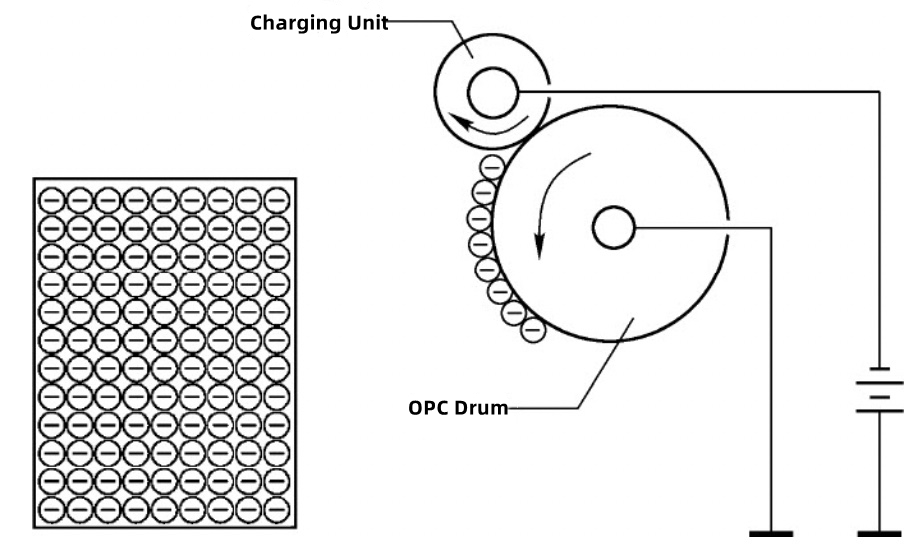

Ake sithathe ukushaja kwerola yokushaja njengesibonelo ukuze siqonde yonke inqubo yokusebenza kwephrinta yelaser.

Okokuqala, ingxenye yesekethe ye-high-voltage ikhiqiza i-voltage ephezulu, eshaja ubuso besigubhu esizwela ukukhanya ngogesi ongemuhle ofanayo ngengxenye yokushaja. Ngemva kokuba isigubhu esizwela ukukhanya kanye ne-charging roller zijikeleza ngokuvumelana umjikelezo owodwa, ubuso bonke besigubhu esizwela ukukhanya bushaja nge-charging engemuhle efanayo, njengoba kuboniswe kuMfanekiso 2-14.

Umfanekiso 2-14 Umdwebo weskimu wokushaja

2>. ukuvezwa

Ukuvezwa kwenziwa eduze kwesigubhu esizwela ukukhanya, esivezwa ngomsebe we-laser. Ubuso besigubhu esizwela ukukhanya buyingqimba ezwela ukukhanya, ungqimba oluzwela ukukhanya lumboza ubuso bomqhubi we-aluminium alloy, kanti umqhubi we-aluminium alloy uphansi.

Isendlalelo esizwela ukukhanya yinto ezwela ukukhanya, ebonakala ngokuba yi-conductive uma ivezwa ekukhanyeni, kanye nokuvikela ngaphambi kokuvezwa. Ngaphambi kokuvezwa, ishaja efanayo ishajwa yidivayisi yokushaja, futhi indawo ekhanyiselwe ngemuva kokukhishwa yi-laser izoba umqhubi ngokushesha futhi ihambisane nomqhubi we-aluminium alloy, ngakho-ke ishaja ikhishwa phansi ukuze yakhe indawo yombhalo ephepheni lokuphrinta. Indawo engakhanyiselwanga ukukhanya yi-laser isagcina ishaja yokuqala, yakha indawo engenalutho ephepheni lokuphrinta. Njengoba lesi sithombe somlingiswa singabonakali, sibizwa ngokuthi isithombe esifihliwe se-electrostatic.

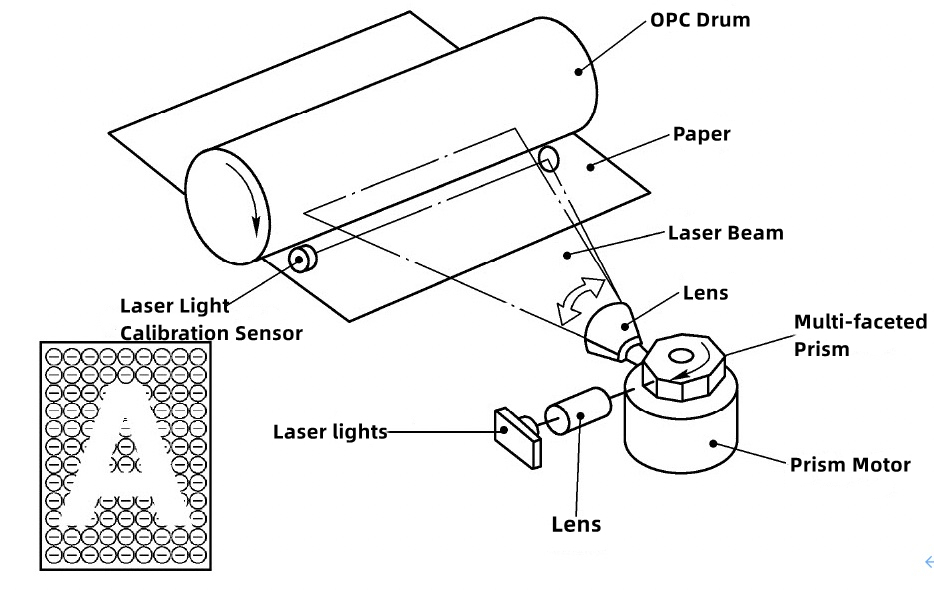

Kufakwe nenzwa yesignali ehambisanayo kusikena. Umsebenzi walesi senzwa ukuqinisekisa ukuthi ibanga lokuskena liyahambisana ukuze ugongolo lwe-laser olukhanyiswa ebusweni besigubhu esinokukhanya lukwazi ukufeza umphumela omuhle kakhulu wokuthwebula izithombe.

Isibani se-laser sikhipha umsebe we-laser onolwazi lwezinhlamvu, olukhanya ku-prism ekhanyayo enezinhlangothi eziningi ejikelezayo, kanti i-prism ekhanyayo ikhombisa umsebe we-laser ebusweni besigubhu esizwela ukukhanya ngeqembu lelensi, ngaleyo ndlela iskena isigubhu esizwela ukukhanya ngokuvundlile. Injini eyinhloko iqhuba isigubhu esizwela ukukhanya ukuze sijikeleze njalo ukuze kutholakale ukuskena okuqondile kwesigubhu esizwela ukukhanya ngesibani esikhipha ukukhanya nge-laser. Isimiso sokuchayeka siboniswe kuMfanekiso 2-15.

Umfanekiso 2-15 Umdwebo weskimu wokuvezwa

3>. intuthuko

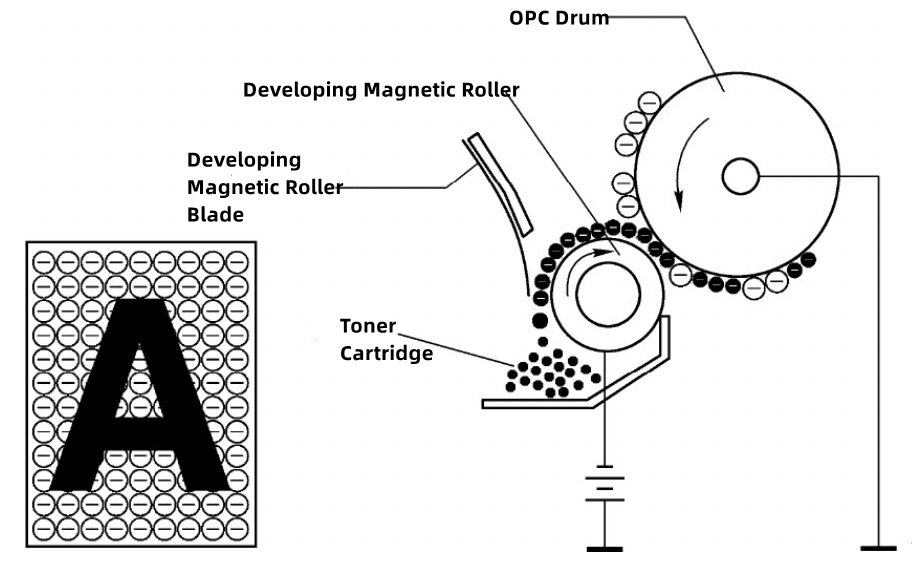

Intuthuko inqubo yokusebenzisa isimiso sokuxoshwa kwabantu bobulili obufanayo kanye nokukhangwa kwabantu bobulili obuhlukile kwamacala kagesi ukuze kuguqulwe isithombe esifihliwe se-electrostatic esingabonakali emehlweni enyama sibe yimifanekiso ebonakalayo. Kukhona idivayisi yemagnethi phakathi kwe-magnetic roller (ebizwa nangokuthi i-developing magnetic roller, noma i-magnetic roller ngamafuphi), futhi i-toner esebhokisini lempuphu iqukethe izinto zemagnethi ezingamuncwa yimagnethi, ngakho-ke i-toner kumele idonswe yimagnethi ephakathi kwe-magnetic roller ekhulayo.

Uma isigubhu esinokukhanya sijikeleza siye endaweni lapho sithinta khona i-roller yamagnetic ekhulayo, ingxenye yobuso besigubhu esinokukhanya esingakhanyiswa yi-laser ine-polarity efanayo ne-toner, futhi ngeke imunce i-toner; kuyilapho ingxenye ekhanyiswa yi-laser ine-polarity efanayo ne-toner. Ngokuphambene nalokho, ngokwesimiso sokuxosha abantu bobulili obufanayo kanye nokuheha abantu bobulili obuhlukile, i-toner imuncwa ebusweni besigubhu esinokukhanya lapho i-laser ikhanyiswa khona, bese kwakheka ihluzo ze-toner ezibonakalayo ebusweni, njengoba kuboniswe kuMfanekiso 2-16.

Umfanekiso 2-16 Umdwebo wesimiso sokuthuthukiswa

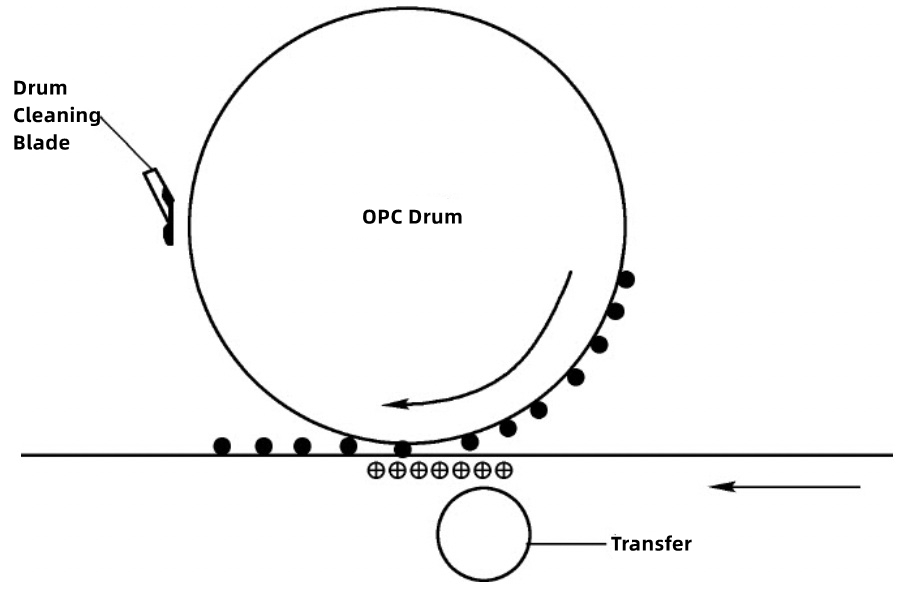

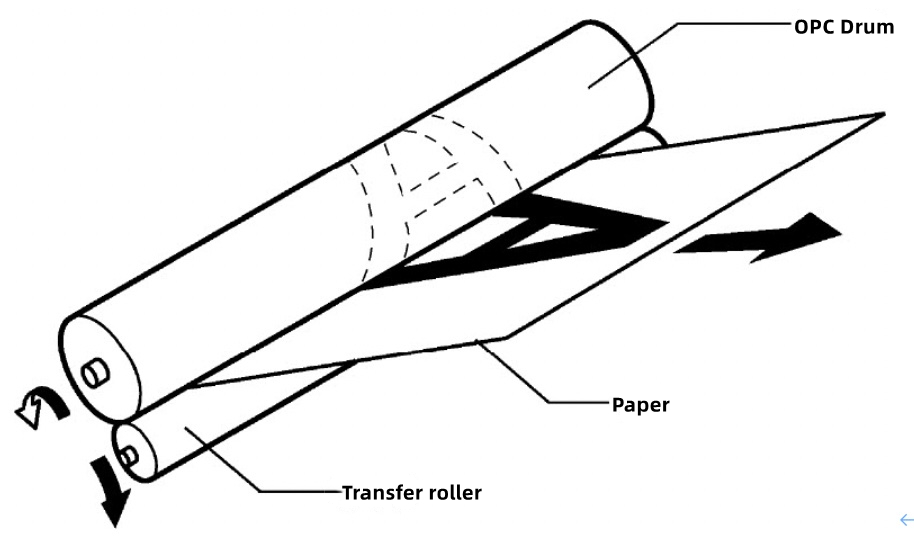

4>. ukuphrinta kokudlulisa

Uma i-toner idluliselwa eduze kwephepha lokuphrinta nge-drum ezwela ukukhanya, kuba nedivayisi yokudlulisa ngemuva kwephepha ukuze kufakwe ukudluliselwa komfutho ophezulu ngemuva kwephepha. Ngenxa yokuthi i-voltage yedivayisi yokudlulisa iphakeme kune-voltage yendawo yokuchayeka ye-drum ezwela ukukhanya, ihluzo, kanye nombhalo owakhiwe yi-toner kudluliselwa ephepheni lokuphrinta ngaphansi kwesenzo sensimu kagesi yedivayisi yokushaja, njengoba kuboniswe kuMfanekiso 2-17. Ihluzo nombhalo kuvela ebusweni bephepha lokuphrinta, njengoba kuboniswe kuMfanekiso 2-18.

Umfanekiso 2-17 Umdwebo weskimu wokuphrinta kokudlulisa (1)

Umfanekiso 2-18 Umdwebo weskimu wokuphrinta kokudlulisa (2)

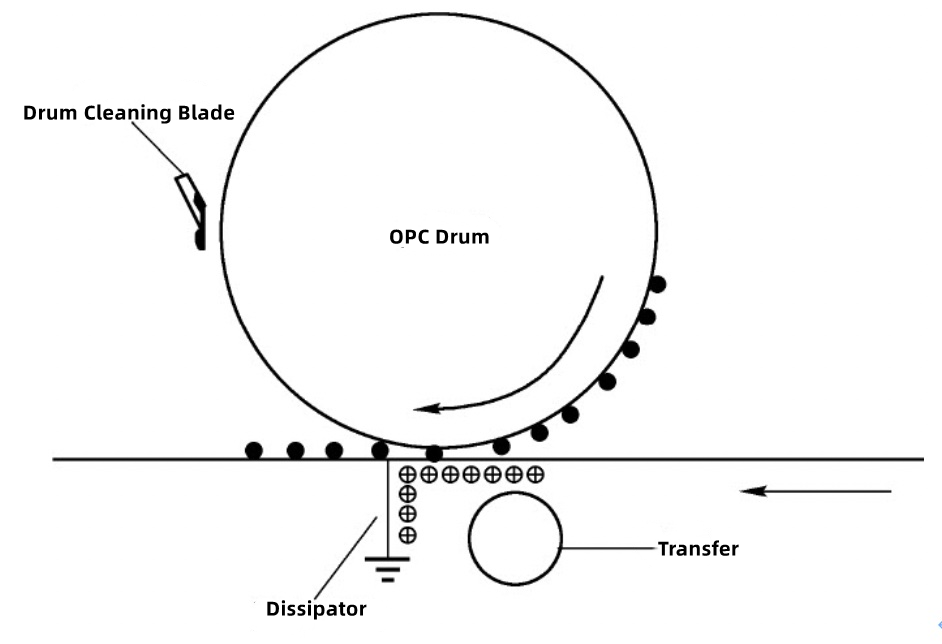

5>. Khipha ugesi

Uma isithombe se-toner sidluliselwa ephepheni lokunyathelisa, i-toner imboza kuphela ubuso bephepha, futhi isakhiwo sesithombe esakhiwe yi-toner sibhujiswa kalula ngesikhathi senqubo yokudlulisa iphepha lokunyathelisa. Ukuqinisekisa ubuqotho besithombe se-toner ngaphambi kokulungisa, ngemva kokudlulisa, sizodlula kudivayisi yokususa engaguquki. Umsebenzi waso ukususa i-polarity, ukuqeda wonke amacala nokwenza iphepha lingathathi hlangothi ukuze iphepha lingene kahle kuyunithi yokulungisa futhi liqinisekise ukuphrinta komkhiqizo. Ikhwalithi yomkhiqizo, iboniswe kuMfanekiso 2-19.

Umfanekiso 2-19 Umdwebo weskimu wokususwa kwamandla

6>. ukulungiswa

Ukushisa nokulungisa inqubo yokufaka ingcindezi nokushisa esithombeni se-toner esifakwe ephepheni lokuphrinta ukuze kuncibilikiswe i-toner bese ifakwa ephepheni lokuphrinta ukuze kwakheke isithombe esiqinile ebusweni bephepha.

Ingxenye eyinhloko ye-toner yi-resin, iphuzu lokuncibilika kwe-toner lingaba ngu-100°C, kanti izinga lokushisa le-heating roller yeyunithi yokulungisa licishe libe ngu-180°C.

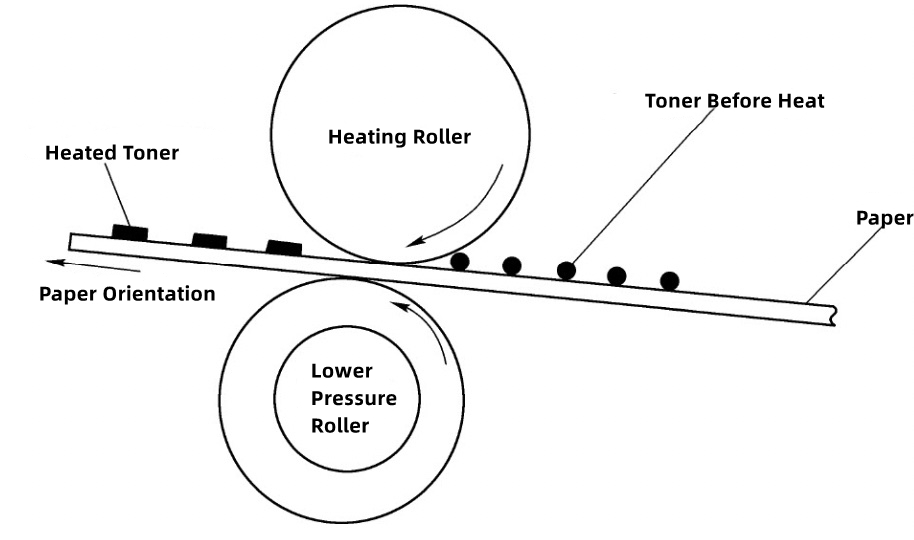

Ngesikhathi senqubo yokuphrinta, lapho izinga lokushisa le-fuser lifinyelela izinga lokushisa elinqunyiwe elingaba ngu-180°C lapho iphepha elimunca i-toner lidlula esikhaleni esiphakathi kwe-heating roller (eyaziwa nangokuthi i-upper roller) kanye ne-pressure rubber roller (eyaziwa nangokuthi i-pressure lower roller, i-lower roller), inqubo yokuhlanganisa izoqedwa. Ukushisa okuphezulu okukhiqizwayo kushisa i-toner, encibilikisa i-toner ephepheni, ngaleyo ndlela kwakha isithombe esiqinile nombhalo, njengoba kuboniswe kuMfanekiso 2-20.

Umfanekiso 2-20 Umdwebo oyinhloko wokulungiswa

Ngenxa yokuthi ubuso be-heating roller bumbozwe nge-coating okungelula ukuyinamathelisa kwi-toner, i-toner ngeke inamathele ebusweni be-heating roller ngenxa yokushisa okuphezulu. Ngemva kokulungisa, iphepha lokuphrinta lihlukaniswa ne-heating roller ngozipho lokuhlukanisa bese lithunyelwa ngaphandle kwephrinta nge-paper feed roller.

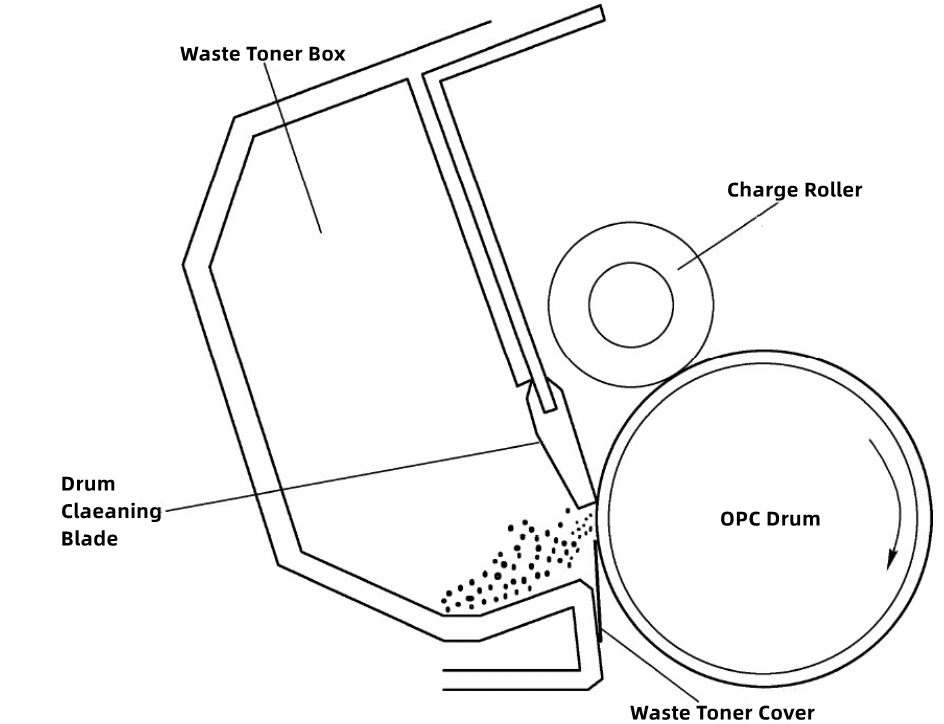

Inqubo yokuhlanza iwukuklwebha i-toner esigubheni esizwela ukukhanya esingakadluliselwa kusuka ebusweni bephepha kuya ebhodleleni le-toner likadoti.

Ngesikhathi senqubo yokudlulisa, isithombe se-toner esigubheni esinokukhanya asikwazi ukudluliselwa ngokuphelele ephepheni. Uma singahlanzwa, i-toner esele ebusweni besigubhe esinokukhanya izothwalwa iye emjikelezweni olandelayo wokuphrinta, ibhubhise isithombe esisanda kukhiqizwa. , ngaleyo ndlela ithinte ikhwalithi yokuphrinta.

Inqubo yokuhlanza yenziwa nge-raber scraper, umsebenzi wayo ukuhlanza i-drum ezwela ukukhanya ngaphambi komjikelezo olandelayo wokunyathelisa i-drum ezwela ukukhanya. Ngenxa yokuthi i-blade ye-raber cleaning scraper ayigugi futhi iyaguquguquka, i-blade yakha i-engeli esikiwe kanye nobuso be-drum ezwela ukukhanya. Lapho i-drum ezwela ukukhanya ijikeleza, i-toner ebusweni ikrwelwa ebhodweni le-waste toner yi-scraper, njengoba kuboniswe kuMfanekiso 2-21 obonisiwe.

Umfanekiso 2-21 Umdwebo weskimu wokuhlanza

Isikhathi sokuthunyelwe: Feb-20-2023